All accessories

Preventive Maintenance Kits

The necessary original spare parts and step-by-step instructions to complete the recommended annual maintenance on you plate processor, to keep it in top running condition.

Delivery table

The delivery table manages the processed plates while the operator feed plates to the processor. It is mounted at the processor exit and collect plates as they have been processed. For automatic online configurations it is recommended to use a stacker instead, which can handle a higher capacity.

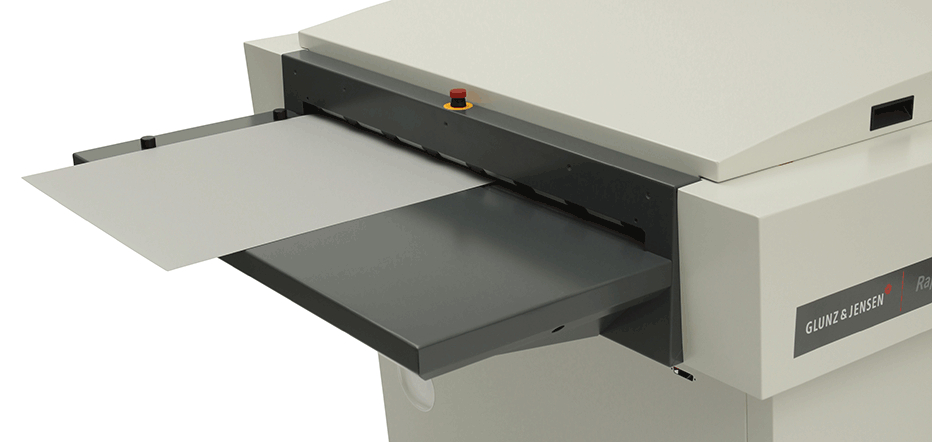

Feed table

Easy feeding of plates into the processor when it is used in an offline or manual configuration by adding a table surface/top for resting plates onto when they are fed into the processor.

For inline configurations you can use a conveyor to connect with the CtP, instead of a feed table.

Remote enabling system

Monitor, correct settings and diagnose the condition of the processor via the local network or modem, for example check chemistry, replenish and waste/water levels, temperatures, or if there is a plate jam.

Closed stand

Keep your pre-press room tidy and organized by hiding the containers with easily fitted side panels. Are easily removed without tools to give full access to the space under the processor.

Plate stacking

Several models of stackers are available, including everything from a convenient compact stacker to a heavy-duty VLF stacker, meeting your every plate stacking need.

Online interface

Safe unattended production. The CtP will only make a new plate if the processor is able to accept it. In the case of a unforeseen event in the line which prevents further processing, the condition is signaled back to the CtP which will stop further plate making. Just order the online interface It is a mechanical AND electrical adaption to the CtP for online installations

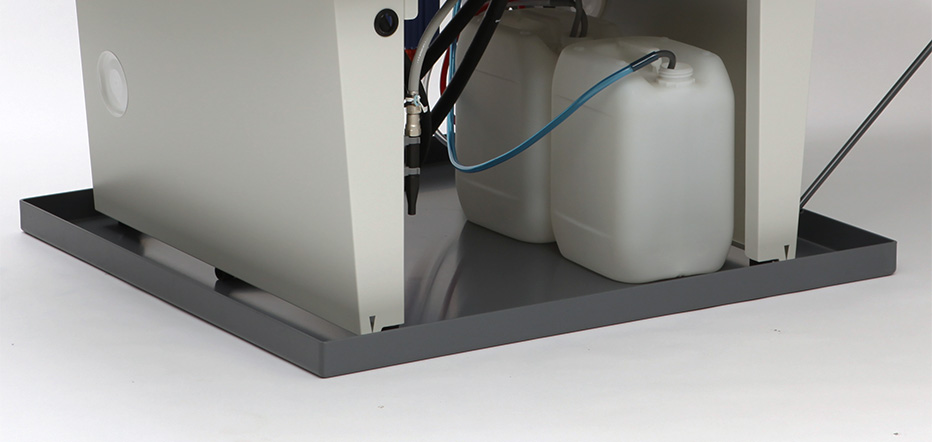

Drip tray

Keep your pre-press room tidy and organized with a drip tray which lay on the floor below the processor to collect and hold fluids which are accidentally spilled onto the floor.

Air management system

With the push of a button on the operator panel the air supply is opened and closed automatically, controlling the airflow to the mounting cylinder. It saves time and more important, it avoids high noise levels when taking off the air supply from the cylinder.

Sleeve change system

By pushing the lever on the dividing head, the cylinder gets slightly lifted at the end. With the push of a button, the left cylinder support is opened and the sleeve can easily be changed.

Water saving

Simple (reversible) convertion to Violet chemfree processing with the optional convertion kit.

Chemfree convertion

Simple (reversible) convertion to Violet chemfree processing with the optional convertion kit.

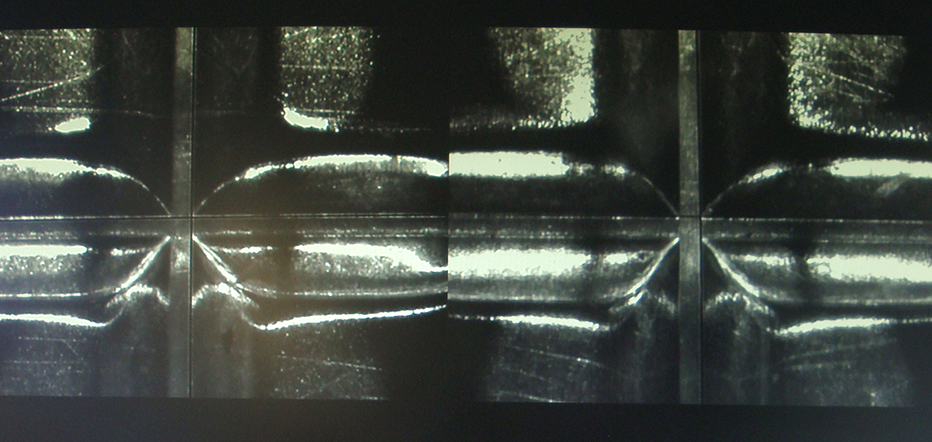

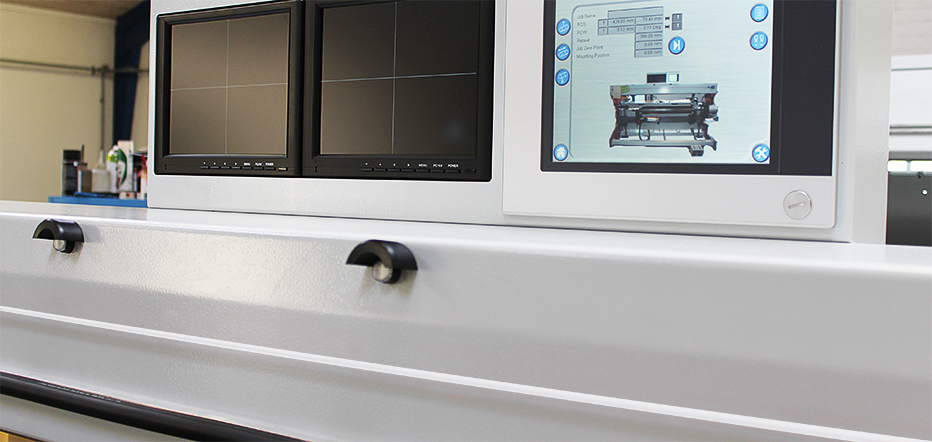

LCD Monitor

LCD monitor with 40 times magnification. A digital readout displays exact position for the operator.

Manually Adjustable

The shaft height in the FlexMount is manually adjustable.

Fiber Optic

Fiber optic, LED light spots project onto the plate surface for quick pre-positioning.

Developer filter

Keep your developer clean and avoid print imperfections caused by deposits on the offset plate.

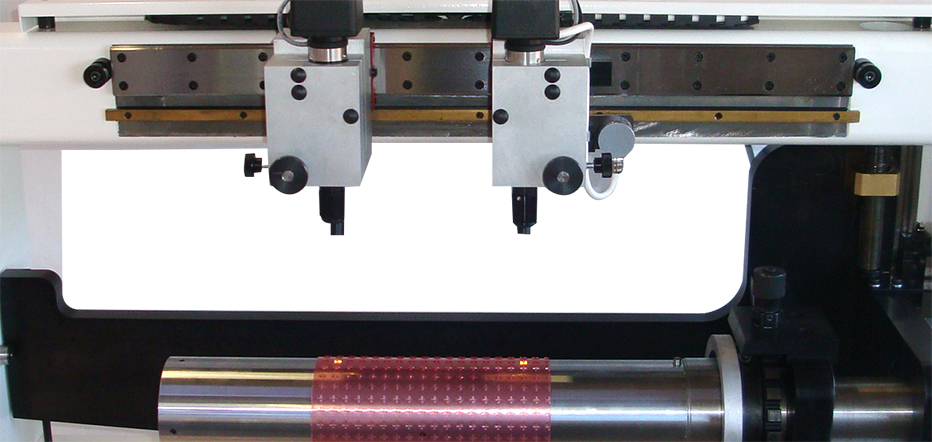

Computer-controlled Cameras

The two cameras in the FlexMount are computer-controlled and motor-driven, which ensures fast and accurate positioning.

Operator Panel

Up to 2000 jobs can easily be registered in the operator panel of the FlexMount. Data can be retrieved and uploaded as spread sheets.

Torque Motor

The maintenance free torque motor for positioning plates has an abolute position of ± 0,011mm on a repeat of 580mm. The motor contains no gears, minimising

overall wear.

Mounting Strip

The ergonomically sound Fast Mounting Strip can be reached from anywhere, regardless of the operator’s position. The Fast Mounting Strip supports the operator by intuitively going through the mounting process step-by-step.

Exend gum cycle

Dual-container System uses two containers simultaneously to extend the gum replacement cycle.

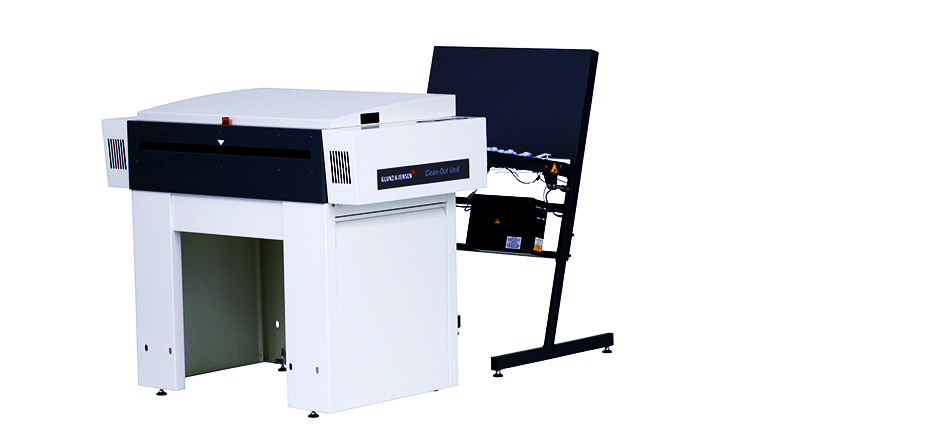

Fully integrated with stacker and CtP

Fully integratable with CtP and stacker or available as manual offline solution.